Thermal Interface Materials for Efficient Heat Transfer

In today’s fast-moving tech world, keeping devices cool is more important than ever. Every part of an electronic device matters, but heat management is often forgotten. As processors get faster and more powerful, they generate more heat, which can affect performance and lifespan.

That’s where Thermal Interface Materials (TIMs) come in. These special materials help transfer heat between components, preventing overheating and keeping devices running smoothly.

Whether you’re an engineer designing new technology or just curious about how gadgets work, understanding TIMs can give you useful insights. Let’s explore why they’re so important in modern electronics.

Importance of Efficient Heat Transfer in Electronics

Efficient heat transfer is crucial for maintaining the performance and reliability of electronic devices. As components generate heat during operation, poor heat management can lead to thermal throttling, reduced lifespan, or even failure.

With electronics becoming smaller and more powerful, effective cooling solutions are more important than ever. High temperatures can degrade materials and cause serious malfunctions, especially in critical industries like aerospace and automotive, where safety is a top priority.

Proper heat dissipation ensures devices run efficiently, preventing energy waste and reducing long-term operational costs. In short, efficient heat management isn’t just about cooling—it’s key to maximizing performance and durability across various tech applications.

Types of Thermal Interface Materials

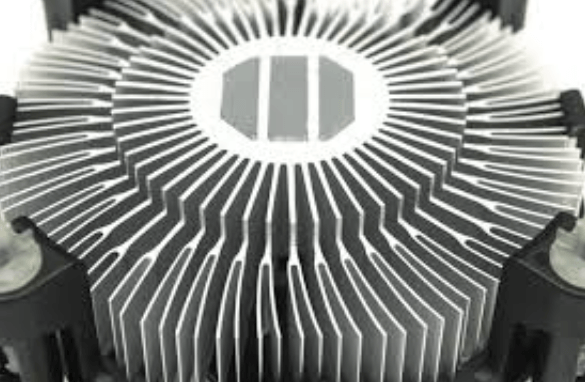

Thermal Interface Materials (TIMs) enhance heat transfer between electronic components and heat sinks by filling microscopic air gaps. This prevents heat buildup and improves efficiency. Different types of TIMs offer unique benefits, making them essential for optimal cooling in electronics.

- Thermal Grease (Paste): A highly conductive paste that fills surface imperfections for optimal heat transfer. It’s widely used in CPUs and GPUs due to its superior thermal performance.

- Thermal Pads: Solid, pre-cut materials that provide consistent heat conductivity and are easy to apply. They are ideal for components requiring low maintenance.

- Phase Change Materials (PCMs): These remain solid at room temperature but soften or liquefy when heated, ensuring better thermal contact by adapting to surface textures.

- Metal-Based TIMs: Made from materials like liquid metal or indium, these offer exceptional thermal conductivity. They are used in high-performance applications but require careful handling to prevent short circuits.

Selecting the right TIM depends on factors like thermal performance, ease of application, and maintenance requirements. The right choice ensures efficient cooling and enhances the longevity of electronic devices.

Benefits of Using TIMs in Heat Transfer

Thermal Interface Materials (TIMs) play a crucial role in managing heat dissipation in electronic devices. Here are the major benefits they offer:

1. Enhanced Thermal Conductivity

TIMs fill tiny air gaps between surfaces, reducing heat buildup and improving cooling. This helps components like CPUs, GPUs, and heatsinks transfer heat more efficiently.

2. Improved Device Longevity

TIMs help keep devices cool by preventing overheating. This protects components from damage, making electronics last longer and reducing the risk of overheating-related failures.

3. Increased Energy Efficiency

Better heat dissipation allows systems to run at optimal temperatures, reducing the need for additional cooling solutions. This leads to lower power consumption and improved overall performance.

4. Ease of Application

TIMs come in various forms—thermal pastes, pads, phase change materials (PCMs), and liquid metal—each suited for different applications. Their flexible application methods make them user-friendly for both professionals and everyday users.

5. Versatility Across Industries

TIMs are widely used in consumer electronics (smartphones, laptops), automotive systems (EV battery cooling), industrial machinery, and high-performance computing (data centers, gaming PCs), demonstrating their broad applicability.

Selecting the right TIM ensures efficient heat management, enhanced performance, and sustainability, making it an essential component in modern thermal solutions.

Read also: Techoelite.Com: Techoelite.Com: Leading the Way in Tech Solutions and Reviews

How to Properly Apply TIMs for Maximum Effectiveness

Applying Thermal Interface Materials (TIMs) properly is important to ensure optimal heat dissipation and prevent overheating in electronic components. Follow these essential steps for effective application:

1. Clean the Surfaces

Before applying Thermal Interface Material (TIM), it’s important to clean both the heatsink and the component (like a CPU or GPU). Dust, grease, or residue can block proper heat transfer, reducing efficiency.

2. How to Clean Properly:

- Use isopropyl alcohol (90% or higher) to remove dirt and grease.

- Apply the alcohol to a lint-free cloth or microfiber wipe (avoid paper towels, as they leave fibers).

- Gently wipe both surfaces until they are completely clean and dry.

A smooth, clean surface helps TIM work effectively by ensuring full contact and preventing air pockets that can trap heat.

3. Apply the Right Amount of TIM

Applying too much TIM can trap heat instead of transferring it, while too little can leave air gaps that reduce cooling. For CPUs, a small pea-sized drop is usually enough for effective heat transfer.

4. Choose the Best Application Method

Applying TIMs correctly is essential for optimal heat transfer. Different methods ensure proper coverage depending on the type of processor or heat-generating component:

- Dot Method: A small dot of TIM is placed in the center of the chip. When the heatsink is installed, pressure spreads the material evenly. This method is commonly used for CPUs.

- Line Method: A thin line of TIM is applied along the center of elongated chips, such as GPUs or certain laptop processors, ensuring even distribution under pressure.

- Spread Method: TIM is manually spread using an applicator or spatula for full surface coverage. This method is preferred when precise application is needed, ensuring no gaps or air pockets.

Choosing the right technique helps maximize thermal efficiency and prevent overheating.

5. Attach the Heatsink Carefully

Gently press the heatsink onto the component without sliding or shifting. Allow the pressure to spread the TIM naturally, filling microscopic gaps for optimal heat conduction.

6. Avoid Excessive Pressure

Over-tightening the heatsink can cause excessive TIM to squeeze out, leading to inefficient thermal transfer or potential damage to the component. Use balanced, firm pressure while securing the heatsink in place.

A properly applied TIM layer reduces thermal resistance, improves heat dissipation, and extends component lifespan. For best results, periodically check and reapply TIM when needed, especially in high-performance applications like gaming PCs or industrial electronics.

Latest Innovations in TIM Technology

The field of Thermal Interface Materials (TIMs) is rapidly evolving to meet the increasing demands for efficient heat management in high-performance electronics. Key innovations include:

- Phase Change Materials (PCMs): Smart TIMs that shift between solid and liquid states based on temperature, enhancing heat transfer without extra components. Ideal for high-performance computing and power electronics.

- Nanotechnology Integration: Using materials like graphene and carbon nanotubes helps transfer heat more effectively while staying flexible. This improves cooling in small but powerful devices, preventing overheating and ensuring better performance.

- Liquid Metal TIMs: Gallium-based alloys offer superior conductivity for extreme cooling applications. Used in HPC, gaming, and aerospace but requires careful handling due to electrical conductivity risks.

- Eco-Friendly TIMs: Biodegradable and sustainable materials reduce environmental impact while maintaining high efficiency. Suitable for consumer electronics and green industries.

- 3D-Printed TIMs: Customizable TIM structures enhance thermal performance in specialized applications like aerospace and medical devices.

As technology advances, these innovations will drive better heat dissipation, improving the efficiency and longevity of electronic devices.